Material Choices & Specifications

Pannam’s sales and engineering team can guide you through the process of specifying materials and components for your user interface assembly. Our application engineers work close with you to understand your requirements and recommend the most cost-effective solution to meet those requirements.The links below provide technical data to help you determine the suitability of various materials and components for the end-use application in which they must operate.

Keypad Overlay Materials

Polyester

- The material of choice for membrane keypad overlays due to its superior flex life and chemical resistance

- Most common thicknesses are .006”, .007”, .008” and .010”

- Certain films are suitable for outdoor use with UV inhibitors for resistance to the UV effects of sunlight.

- Available with built-in Microban antimicrobial protection that inhibits growth of bacterial, mold & mildew.

- Also available in brushed finish to simulate the look of brushed metal

- Special “soft touch” surface finish available to mimic the feel of silicone rubber

Autotype Polyester Products

- Autotex V and Autotex F (textured)

- Autoflex EBG/EBA (gloss and antiglare surface finishes)

- Autotex XE (with UV inhibitors for outdoor use)

- Autotex Steel (brushed finish)

- Autotex AM (with antimicrobial protection)

- Autotex Softouch (mimics the feel of silicone rubber)

Tekra Polyester Products

Polycarbonate

- Ideal for standalone display windows, overlays without keypads as well as bezel overlays for rubber keypads

- Available in textured, antiglare and glossy finishes

- Certain films are suitable for outdoor use with UV inhibitors for resistance to the UV effects of sunlight.

- Available in an anti-fog coating

- Available in thickness ranges from .005” to .030”

- Lexan 8B35 (textured)

- Lexan 8B35F (textured)

- Lexan 8B35V (textured)

- Lexan HP (hardcoated antiglare and glossy)

- Lexan HPFAF (anti-fog)

- Lexan HP12W (with UV inhibitors for outdoor use)

- Marnot XL Hardcoat Clear Polycarbonate

- Marnot XL Hardcoat Matte Polycarbonate (20, 35, 55, 75 and 90 Gloss Unit matte levels)

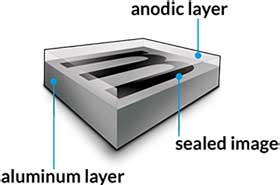

Metalphoto Anodized Aluminum

- Ideal for Dynapic piezoelectric keypads for harsh, abusive, and outdoor applications

- Available in Satin, Matte, #4 (brushed), and Gloss finishes

- Resists abrasion, chemicals, salt spray, sunlight, heat and humidity

- Specified for many military standards and aerospace applications

- Click here for performance characteristics of Metalphoto keypad overlays

Printed Coatings & Textures

- Fototex UV Matte – Used for printing selective textured patterns on membrane switch overlays. It has excellent scratch and chemical resistance

- Windotex Antiglare and Gloss – used to print clear windows onto textured graphic overlay surfaces

Membrane Switch Circuit Materials

The most common circuitry material is heat stabilized polyester, typically in .005” or .007” thickness.

Adhesives Transfer Tapes

3M 200MP High Performance Adhesives

- Suitable for high surface energy materials such as aluminum, steel, polycarbonate, ABS, nylon, etc.

- Widely used in the membrane switch applications

- Available in thicknesses of .002” and .005”. For adhesion to textured surfaces the .005” thickness is recommended.

- Service temperature range of -31°F to +300°F for prolonged periods and +400°F for short periods.

- Excellent environmental, temperature, chemical and humidity resistance

3M 300LSE High Strength Adhesives

- Ideal for adhesion to low surface energy plastics such as powder coated paint and polypropylene

- Available I nthicknesses of .002”, .0035”, and .005”. For adhesion to textured surfaces the .005” thickness is recommended.

- Service temperature range of -40°F to +200°F for prolonged periods and +300°F for short periods.

- Excellent environmental, temperature, chemical and humidity resistance.

Membrane Switch Spacers & Dielectric Tail Tapes

- Outstanding adhesion to metal and high surface energy plastics

- Up to 400°F short-term heat resistance

- Excellent solvent resistance

- Excellent shear strength to resist slippage and edge lifting

Membrane Switch Components

Connector Pins

Connector Housings (used in conjunction with Pins)

Metal Domes

LEDs

Support Panel Fasteners

Fiber Optic Lamps