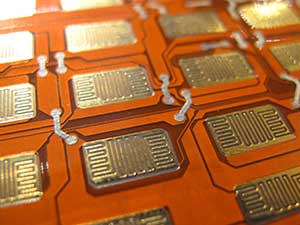

Copper Flex Membrane Switches

What are Copper Flex Membrane Switches?

Copper Flex membrane switch panels can be produced using polyester or polyimide (Kapton) as the base material, depending on your interface requirements. A very thin sheet of copper is laminated to the flexible film substrate then chemically etched away, leaving copper traces. The etching process is not environmentally friendly due to the chemicals used, and is also more expensive than screen printing the silver traces used in Silver Flex membrane switches. Copper Flex switches can be constructed as:

- Single-sided – conductive traces one side of the film substrate

- Double-sided – conductive traces both sides of the film substrate

- Multi-Layer flex – a laminated “sandwich” of numerous layers with conductive traces

- Rigid-Flex – a laminated combination of a Copper Flex switch with a rigid FR4 PCB membrane switch

What are the Advantages of Copper Flex Membrane Switches?

Copper Flex membrane switches are ideal for smaller designs where dense circuit patterns or trace routing limitations exist. This design also allows the ability to accommodate the complex circuit patterns of a FR4 rigid printed circuit board with the flexibility of a membrane switch. Copper Flex keypads also have the advantage of being able to hard solder active and passive components into the assembly, making it a good choice in high-vibration, high-reliability environments

What are the Copper Flex Membrane Switch Design Options & Considerations?

Single-sided, double-sided, and multi-layer designs available

- Lower electrical resistance and higher conductivity vs. traditional Silver Flex membrane switches

- Tight trace routing capabilities

- Same thin profile and flexibility as Silver Flex Membrane Switches

- Plating options can be tin-lead, nickel, or gold

- Tactile and non-tactile with either metal or polyester tactile domes

- Pillow or rim-embossed graphic overlays

- LEDs and other components can be soldered and are more robust

- Graphic overlays that can be digitally printed, screen printed, or a combination of both

- The graphic overlays can incorporate transparent and tinted display windows, as well as selective textures and UV hardcoat surface finishes

What are the Copper Flex Membrane Switch Design Options & Considerations?

| Characteristic | Silver Flex | Copper Flex |

|---|---|---|

| Printing vs. Etching | Conductive silver ink traces are screen printed onto the film substrate. | A sheet of copper is chemically etched away, leaving conductive traces. More expensive than screen printing. |

| Pliability/Weight | Silver traces are lightweight and more flexible than solid copper traces. | Solid copper traces are heavier and more durable than softer printed silver traces. |

| Conductivity | Resistivity approx 50 mOhms/sq 1mm x 80 mm trace = 4 Ohms 0.5mm x 80mm trace = 8 Ohms | Lower electrical resistance and higher conductivity. |

| Price | Low to Moderate | Expensive to very expensive |

| Soldering | No. Components are attached with conductive adhesive. | Ability to solder active and passive components into the switch design. |

| Pitch | Minimum of 1.0mm | Possible pitch 0.5mm and 0.3mm for ZIF connector |

Single-sided, double-sided, and multi-layer designs available

Single-sided, double-sided, and multi-layer designs available