Silver Flex membrane switches are the most common construction for flexible, custom membrane keypads. It is also the most popular membrane switch construction due to its affordability. But what exactly are the parts that make up a membrane switch? What design options are available for each of these pieces? And what are the benefits of a Silver Flex membrane switch? For the answers to all these questions, see the infographic below.

Full Infographic Text:

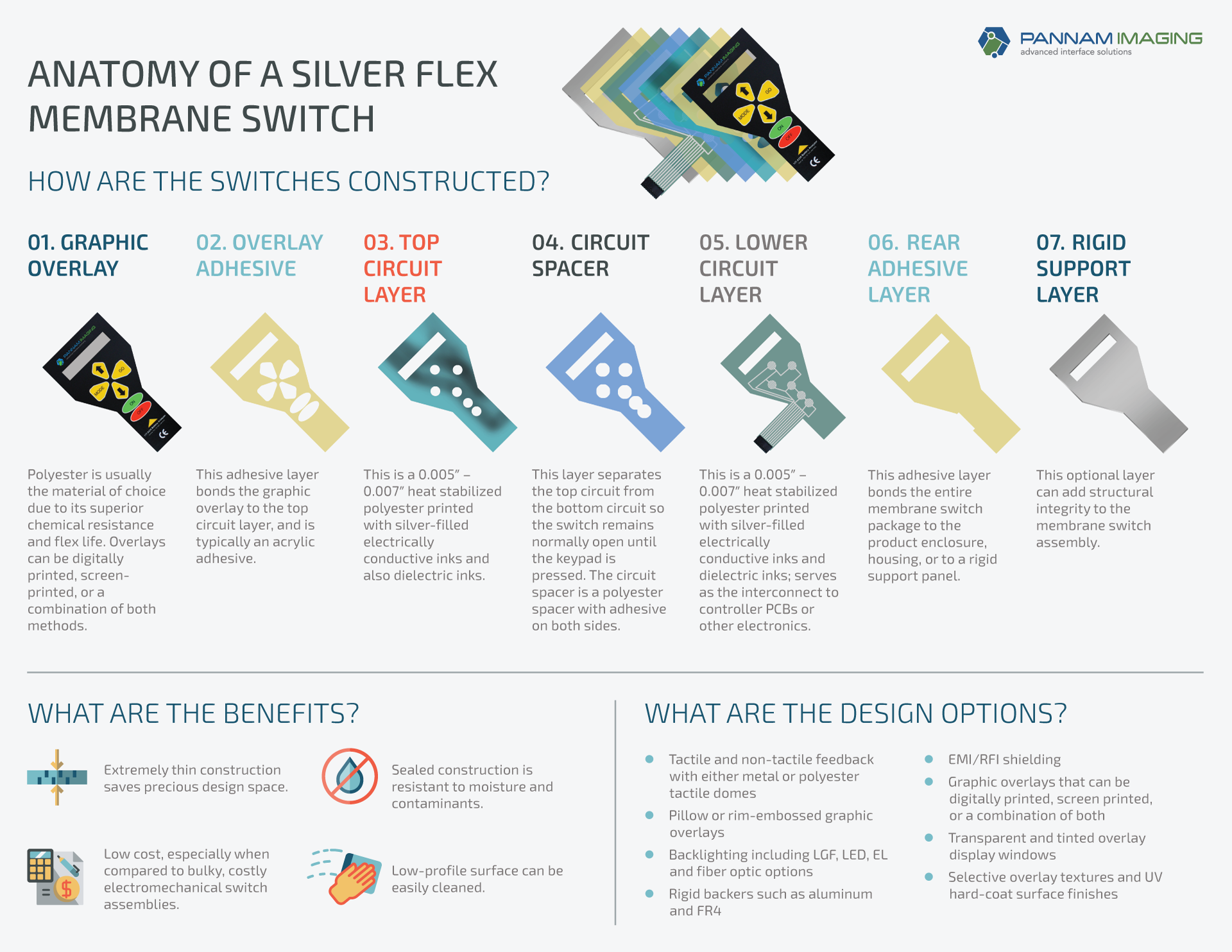

Anatomy of a Silver Flex Membrane Switch

How are the Switches Constructed?

- Graphic Overlay

Polyester is usually the material of choice due to its superior chemical resistance and flex life. Overlays can be digitally printed, screen- printed, or a combination of both methods. - Overlay Adhesive

This adhesive layer bonds the graphic overlay to the top circuit layer, and is typically an acrylic adhesive. - Top Circuit Layer

This is a 0.005” – 0.007” heat stabilized polyester printed with silver-filled electrically conductive inks and also dielectric inks. - Circuit Spacer

This layer separates the top circuit from the bottom circuit so the switch remains normally open until the keypad is pressed. The circuit spacer is a polyester spacer with adhesive on both sides. - Lower Circuit Layer

This is a 0.005” – 0.007” heat stabilized polyester printed with silver-filled electrically conductive inks and dielectric inks; serves as the interconnect to controller PCBs or other electronics. - Rear Adhesive Layer

This adhesive layer bonds the entire membrane switch package to the product enclosure, housing, or to a rigid support panel. - Rigid Support Layer

This optional layer can add structural integrity to the membrane switch assembly.

What are the Benefits?

- Extremely thin construction saves precious design space.

- Sealed construction is resistant to moisture and contaminants.

- Low cost, especially when compared to bulky, costly electromechanical switch assemblies.

- Low-profile surface can be easily cleaned.

What are the Design Options?

- Tactile and non-tactile feedback with either metal or polyester tactile domes

- Pillow or rim-embossed graphic overlays

- Backlighting including LGF, LED, EL and fiber optic options

- Rigid backers such as aluminum and FR4

- EMI/RFI shielding

- Graphic overlays that can be digitally printed, screen printed, or a combination of both

- Transparent and tinted overlay display windows

- Selective overlay textures and UV hard-coat surface finishes