Some are calling it the Hardware Revolution. As the Internet of Things and wearables take off, hardware is seeing a resurgence similar to the software boom of ten years ago. Some software developers are even jumping into the hardware design game, as they are designing specifically for hardware products. Whether you’re new to hardware product design and manufacturing or a seasoned pro looking for the latest news, developments, and innovations, our top 50 resources will help you learn more about how to design and manufacture hardware products.

We have searched for resources from top thinkers and industry leaders, including electrical engineers and designers, to compile our list of hardware product design and manufacturing tips. Below, you will find everything from articles and blogs to videos and webinars – we’ve even added some hardware design/manufacturing events. Here at Pannam, we hope these top resources on how to design and manufacture hardware products will inspire you to begin your next project.

While we have listed our top resources on how to design and manufacture a hardware product in no particular order, we have included a table of contents to make it easier for you to jump to the resources categories that are of most interest to you.

Jump to:

- Articles

- Blogs

- Communities, Forums, and Events

- Design Tool, Interactive Infographic, and Online Course

- eBooks and White Papers

- Podcasts, Videos, and Webinars

- Tips

Articles

1. 5 Lessons I Learned at Apple About How to Design and Build Hardware

@billbanta

@gigaom

Bill Banta, a Gigaom guest contributor, has worked at Square and Apple. Currently the CEO of CENTR Cameras and the Co-Founder and CEO of StealthHD, Banta knows a thing or two about designing and building hardware. In this resource for designing and manufacturing a hardware product, Banta actually shares five things he knows about the subject. One of his tips that stands out most to us is to “fire any engineer that ever says ‘it’s not possible.’ That no-can-do mentality has no place at an innovative startup.” He firmly believes that innovative hardware organizations require people who are motivated and willing to push the envelope.

Three key tips we like from 5 Lessons I Learned at Apple About How to Design and Build Hardware:

- Go into the factory and onto the manufacturing floor and talk to the line managers and operators to refine product design for better manufacturability

- Prototype close to home so that you can refine as much as necessary and enable your engineering team to iterate faster

- Consider manufacturing opportunities that are close to your customers

Cost: FREE

2. From Idea to Product: 10 Steps for Creating a Hardware Company

@makingsociety

While you may be considering just how to make a product, many hardware makers wind up starting a hardware company. This article from MakingSociety breaks down the process for launching a hardware company into 10 steps or phases. One feature that we like most about the article is that it includes useful resources for various phases of the process.

Three key points we like from From Idea to Product: 10 Steps for Creating a Hardware Company:

- Make sure that your product solves a need and that you have given it some time before jumping in with both feet

- When you tackle your very first prototype, center on your product’s functions by making the electronics work and creating a rough idea of the product you have in mind

- Be prepared to make several prototype versions and to create some with specific purposes early in your process

Cost: FREE

3. Kicking Down Silos: Co-Designing Software & Hardware to Create Great Products

@PrototypingAndy

Dr. Andy Carle describes himself as a “UX Strategies, Prototype Engineer, Usability Scientist, Gamer.” With an interest in making technology more accessible and useful, Dr. Carle’s guiding philosophy is that “good design for anyone is good design for everyone.” This philosophy is evident in his introduction for Solid, in which he details his first experience co-designing consumer electronics. His takeaway was that “co-designing great hardware and great software leads to products that are far more interesting than the sum of their parts.”

Three key points we like from Kicking Down Silos: Co-Designing Software & Hardware to Create Great Products:

- Transitioning from building apps to building products is difficult

- It is possible for designers to co-design software and hardware, and the correct approach to doing so results in an ability to prototype rapidly, conduct early user tests, and create final products with an eye toward manufacturability and profitability

- Building on existing hardware and software platforms is a development time saver

Cost: FREE

4. The Hardware Renaissance and How Anyone Can Get a Product Concept Manufactured

@hardi_meybaum

The CEO of GrabCAD and author of The Art of Product Design, Hardi Meybaum was a featured speaker at Solid 2014. He strongly supports that people looking to design and manufacture a hardware product should make use of crowdsourcing, crowdfunding, and Open Engineering. These are innovative ways that make it easier to build faster and bring hardware products to market more quickly.

Three key ideas we like from The Hardware Renaissance and How Anyone Can Get a Product Concept Manufactured:

- Crowdsourcing, crowdfunding, and Open Engineering are viable options for building your product two to three times faster

- Use CAD software to make a virtual prototype or 3D print a prototype and start selling your product before looking into large-scale manufacturing

- Draw on the creativity of your engaged customers and outsiders to get new ideas

Cost: FREE

5. Hardware Product Development Process

@chenelaine

Elaine Chen is a startup veteran and an innovation and entrepreneurship consultant. This article for ConceptSpring, the company she founded to “help innovative teams accelerate product development,” serves as the prequel to Chen’s prototyping and manufacturing series. A lengthy article, Hardware Product Development Process walks readers through the process of designing and manufacturing a hardware product and comes from conversations Chen has had with startup teams at MIT.

Three key points we like from Hardware Product Development Process:

- Hardware development and software development are not the same thing, for several reasons

- You should put formal check points, or gate reviews, into your process in order to “assess what you have learned with each phase, and decide whether you will go forward and spend the next $500k.”

- During the engineering prototyping phase, which should take place in your own facility, you should incorporate design for manufacturing thinking into the engineering development work

Cost: FREE

6. Designing Software and Hardware At Once

@FastCoLabs

@FastCompany

FastCo.Labs is Fast Company’s experimental code and content lab. Their article, Designing Software and Hardware At Once, explains that “integrated experiences are inherently both physical and digital, but ‘integration’ doesn’t mean doing everything at once.” They share the thoughts of three designers who explore the implications of combining physical products with digital goods and making them easier to sell.

Three key points we like from Designing Software and Hardware At Once:

- There needs to be an understanding of how products with physical and digital components deliver “a much more interactive and meaningful experience”

- You cannot solve interaction problems with hardware solutions, or you’ll get “a lack of congruity between the hardware and the interaction design that the hardware is meant to manipulate and display”

- “The physical product is becoming the talisman for the digital experience”

Cost: FREE

7. Software is Eating Hardware – Lessons for Building Magical Devices

@firstround

FirstRound is building a strong community of technology entrepreneurs and helping startups communicate and connect. A resource on how to design and manufacture a hardware product, their article features companies and thought leaders who see the role of software as being not only integral, but critical, to designing a successful hardware product.

Three key points we like from Software is Eating Hardware – Lessons for Building Magical Devices:

- Companies that are going to succeed in designing and manufacturing a hardware product need to first create beautiful software that “spans mobile, desktop, and more.”

- “Software can reshape the capability of the hardware continuously, exceeding the speed of customer demand.”

- “The best new ideas live at the boundary between the real world and software”

Cost: FREE

8. Applying Agile to Hardware New Product Development Environments: Part 1

@PLAYBOOKHQ

PLAYBOOKHQ delivers lean and agile project management software that helps companies launch their products more quickly. In his article for PLAYBOOK, Eric Graves examines the ability of Agile principles to provide a comprehensive solution for hardware product development. This article also is the first in a series of blog posts that explore the differences between software and hardware product development.

Three key points we like from Applying Agile to Hardware New Product Development Environments: Part 1:

- Agile software development shares some characteristics with Lean hardware product development

- “Lean manufacturing practices can do more harm than good if blindly applied to new product development. The same is true of applying Agile to hardware.”

- Lead time, component cost, and non-homogenous work are three of the main differences between software and hardware development

Cost: FREE

9. Startups: Stop! Don’t hire a design firm!

@BoltVC

Bolt is a “seed-stage fund propelling hardware startups with capital, expert engineering staff, equipment, and manufacturing support.” Written by Ben Einstein, founder and general partner at Bolt, this resource for how to design and manufacture a hardware product explores all of the reasons that young hardware startups should never outsource their product development.

Three key points we like from Startups: Stop! Don’t hire a design firm!:

- To make a successful hardware product, you need to know your users by holding early user conversations, rather than outsourcing your design

- It is up to you to know your product better than anyone else, so you need to take control of the design process in order to be able to predict how early decisions will affect the product down the road

- Agility will help you to succeed, as long as you focus only on the most important things

Cost: FREE

10. Designing Hardware for the Internet of Things

@thinkapps

Written by Katelan Cunningham, a freelance editor who covers technology and design, this article explores how Jawbone founder and CEO Hosain Rahman plans to help Jawbone transform the Internet of Things by designing hardware that is at “the intersection of engineering meets beauty.”

Three key ideas we like from Designing Hardware for the Internet of Things:

- Hardware products need to be compatible with one another so that they are no longer “confined to their own feature set”

- Design products that address users’ needs

- Start with an open, broad process and be as creative as possible while narrowing your focus to your final product

Cost: FREE

11. Hardware By the Numbers: Part 1: Team + Prototyping

@BoltVC

@BenEinstein

Ben Einstein is a product designer who loves hardware. As founder and partner at Bolt, Einstein wrote a four-part series on the ins and out of building a scalable hardware business. In this first part of the series, he seeks to offer more help than simply repeating the tired phrase, “hardware is hard.” And, he does just that by outlining the numbers involved with starting a scalable hardware business, to provide an objective look at the process of building a hardware startup.

Three key points we like from Hardware By the Numbers: Part 1: Team + Prototyping:

- Assembling the team is the most important part of your job as founder

- Start with two founders: a “hacker” and a “dealmaker/hustler,” aka, “a teach person and someone who’s willing to focus on everything else”

- You need to know exactly what and how to prototype to build a better product that will delight users, and to do it in less time with less capital

Cost: FREE

12. Does Open-Design Hardware Have a Place in Manufacturing?

@ArenaSolutions

Arena Solutions helps “innovative companies and their extended supply chains to better manage their Bill of Materials (BOM).” In this resource for designing and manufacturing a hardware product, Arena co-founder and CTO Eric Larkin makes the case for open-design hardware by taking a look at the success and value of open-source software platforms.

Three key points we like from Does Open-Design Hardware Have a Place in Manufacturing?:

- Open-design hardware is king in some markets, which signifies that it could work commercially

- Open-design hardware more than likely will not be a fit for brand name, mass-produced electronic consumer products

- Open-design hardware does have a place in designing and manufacturing in the developing world and in community-backed open design such as Kickstarter

Cost: FREE

13. “Autobox” Hardware Testing Tool

@nuvation

Sometimes, designing and manufacturing a hardware product makes designers realize that the tools they need to complete the process are unavailable. This issue led Daniel Steger to design and create the Autobox, which is his solution to aid in “software development, automated testing, and hardware bring up.” The Autobox is a development tool in and of itself, and it now resides in Nuvation’s hardware testing lab.

Three key ideas we like from “Autobox” Hardware Testing Tool:

- Electronic engineers play important roles in hardware product design and manufacturing

- Specialized tools speed up otherwise manual tasks in the hardware product design and development process

- Automating testing processes is helpful when designing and perfecting a hardware product

Cost: FREE

14. Designing for Smart, Connected Products

@PTC

PTC works to help manufacturers “achieve product and service advantage in the age of the Internet of Things (IoT).” Their award-winning blog, Product Lifecycle Report, features the work of Nancy Pardo, PTC content marketing director and blog manager. In this hardware product design and manufacturing resource, Pardo shares the second of four interviews with PTC CEO Jim Heppelmann on the impacts of the IoT and smart, connected products on product design.

Three key points we like from Designing for Smart, Connected Products:

- Product designers would be wise to “take a holistic systems engineering approach to design across the hardware and software layers of the physical product, and across the physical product and the related cloud services”

- One option for designing for customization is to allow for software-based customization

- It’s important to keep in mind that software innovations may drive increased value in hardware, but hardware development takes a great deal longer than software development

Cost: FREE

15. Entrepreneurs Get Help for Hardware

@Updates2TDF

Tech Design Forum is an online electronics system design resource. In this Tech Design Forum article, Chris Edwards explores how crowdfunding is helping entrepreneurs move into hardware production as well as “spawning incubators who can help streamline product design.” Edwards warns, however, that those looking to design and manufacture a hardware product should be aware of the fact that hardware is not at all compromising, especially when speaking in terms of volume production.

Three key tips we like from Entrepreneurs Get Help for Hardware:

- Founder and CEO of Nest Labs, Tony Fadell, reminds us that a large infrastructure is necessary for shipping a product and all of its associated apps

- Highway 1 founder Brady Forrest points out that most startups’ prototypes are not going to cut it when it comes to mass production in a manufacturing plant because startups rely on 3D printers, rather than CNC machining and moulding equipment

- It is key to learn about competition and to understand successful paths to hardware product design and manufacturing, according to Fadell

Cost: FREE

16. A New Approach to Hardware Design Project Management

@eetimes

Categorized as a design how-to, this EETimes article by Simon Butler addresses the managerial aspects that are required in designing and manufacturing a hardware product. Butler walks readers through the problems of electronics design product management and the way in which Methodics approaches their project management and handles the needs of complex integrated circuit (IC) environments.

Three key ideas we like from A New Approach to Hardware Design Project Management:

- It can be very difficult for organizations to properly organize project data and to properly communicate change

- Tools that focus on the design environment from the designers’ and integrators’ perspectives, plus provide “concise management tools for the IT specialist and project manager” are the most useful

- When design teams multiply and companies merge, it is a challenge to define and manage best practices across teams and design sites

Cost: FREE

17. 2015 Electronic Hardware Development and Manufacturing Trends

@octopart

A search engine for electronic and industrial parts, Octopart provides access to part data in design, sourcing, and manufacturing. In this Octopart blog post, Sam Wurzel reflects on his time spent talking with contract manufacturers, distributors, and manufacturing partners of Octopart. His blog discusses the rapid changes taking place in electronic hardware development and the new trends that are emerging.

Three key ideas we like from 2015 Electronic Hardware Development and Manufacturing Trends:

- The trend of new people, including those who do not have formal training in electrical engineering, are getting into electronics

- Electronic hardware development internet communities are enabling people to share and gain knowledge about hardware design and manufacturing

- Electronic hardware designers have a whole new set of capabilities available to them on their desktops

Cost: FREE

18. Here’s How to Make Hardware Startups More Than Just a Fad

@WIRED

Marc Barros writes in this WIRED article about hardware being all the rage, yet there are some changes that need to be made before the hardware revolution truly can take off. In a very frank manner, Barros addresses the state of hardware design and manufacturing as a fad for niche products and then outlines the issues that need to be addressed in hardware product design and manufacturing.

Three key points we like from Here’s How to Make Hardware Startups More Than Just a Fad:

- Hardware entrepreneurs often don’t accurately predict how difficult it is to bring together a whole system into a “product ready for mass adoption”

- The critical component of a hardware minimum viable product (MVP) is “focusing on a single feature (delivering it better than anyone else) and getting to market quickly (most companies have no idea how well a hardware product will sell until customers start paying) – all while driving positive cashflows”

- Hardware startups need to have access to the same components as established companies

Cost: FREE

19. How Fitbit Survived As a Hardware Startup

@Forbes

@robhof

Robert Hof, Forbes contributor, notes that designing and manufacturing consumer hardware products is anything but easy. He uses Fitbit as an example, as he reports on Fitbit cofounder and CEO James Park’s revelations about the challenges Fitbit faced in getting their product to market.

Three key points we like from How Fitbit Survived As a Hardware Setup:

- Be prepared for it to take you much longer than you anticipate to build up distribution

- There is very little room for error when designing and manufacturing a hardware product, so you must be involved in all of the details; one mistake in hardware eliminates months of progress

- If possible, manufacture multiple models of a hardware product because “a single form factor such as a watch won’t take over”

Cost: FREE

Blogs

20. Bolt Blog

@BoltVC

Bolt is dedicated to helping hardware startups burst onto the scene with manufacturing support, capital, and more. Their blog, Bolt Blog, offers “advice and opinions at the intersection of hardware, software, and startups.” While most of the blog’s content is geared toward hardware startups, the posts contain gems of information that will help even the most seasoned designers and manufacturers.

Three posts we like from Bolt Blog:

- Keurig Accidentally Created the Perfect Business Model for Hardware Startups

- Speed Can Kill: The Importance of Process for Hardware

- Can You Show Traction for a Product You Haven’t Manufactured Yet?

Cost: FREE

21. ByteSnap Blog

@ByteSnap

ByteSnap is an “embedded electronics design consultancy expert in cutting-edge hardware and software development, taking your ideas from mind map to market.” The ByteSnap Blog is a robust resource for designing and manufacturing hardware products, as it includes posts in software design, electronic design, product development and more.

Three posts we like from ByteSnap Blog:

- Five Advantages of Pre-Compliane EMC Testing

- CE Marking – 20 Things You Need to Know

- Design Trade-Offs For Product Development

Cost: FREE

Communities, Forums, and Events

22. Open Compute Project

@OpenComputePrj

Started by Facebook, Open Computer Project (OCP) is an initiative that strives to accelerate data center and server innovation, with the ultimate goal of increasing computing efficiency. The OCP also promotes open source hardware. Their community members use the project “to develop hardware designs based on open specs and designs that are open sourced through the project.” End users benefit from the project because they are able to get custom hardware and lower their costs because multiple vendors supply the same products.

Cost: Contact for community membership pricing

23. Electronics and Electrical Engineering Community Members: Hardware Design

@EE_Web

EEWeb is “a premier electrical engineering community for hardware designers.” The hardware design community of EEWeb gives members the opportunity to network with electronics and engineering experts from dozens of organizations and companies, plus various universities.

Cost: Contact for community membership pricing

24. Semico Impact 2015: Boards, Chips and Packaging: Designing to Maximize Results

@SemicoResearch

October 13

Mountain View, CA

Hardware design and manufacturing are at the heart of this year’s Semico Impact Conference – Boards, Chips and Packaging: Designing to Maximize Results. The preliminary agenda includes keynote speaker Daniel DeAraujo of Mentor Graphics, a panel discussion on getting to next-generation high speed data transfer rates, an afternoon session on the role of mm wave automotive radar, a panel discussion on boards, chips and packaging to meet market requirements, and more.

Cost:

- Pre-Registration: $75

- Walk-Up Registration: $150

25. Electronics/Hardware Development Forum

@cemetech

Cemetech is a community for technology professionals and enthusiasts that also serves as a hardware and software development group. Their forum on electronics and hardware development is an active forum with dozens of users. Guests may read discussion threads, but only registered users may interact with the forum by posting new topics, replying to topics, and more.

Three discussion threads we like from Electronics/Hardware Development Forum:

- 3D Printing a TI-84 Plus Family Slidecase

- Spark Core Development Discussion

- TI-84/TI-89 with an Arduino or Raspberry Pi Brain?

Cost: FREE registration

Design Tool, Interactive Infographic, and Online Course

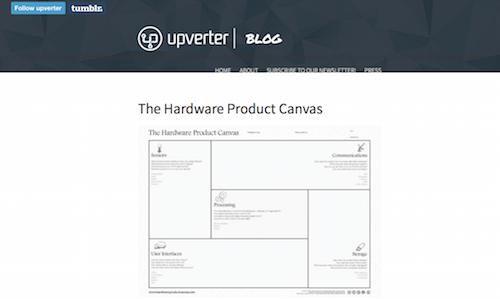

26. The Hardware Product Canvas

@upverter

Upverter supplies engineers with the technology, knowledge, and support they need to accelerate electronics design. One of the features on their blog is their Hardware Product Canvas, a design tool to help users make it “through the earliest stages of a hardware design.”

Three key features we like about the Hardware Product Canvas:

- The Hardware Product Canvas is available for the taking, so you can hack it or use it for your hardware design

- Simple to use by filling in the blanks

- The tool makes hardware product design easy by breaking hardware into its parts: sensors, communication, storage, user interfaces, and processing

Cost: FREE

27. Learn How to Design Hardware

@upverter

Upverter also offers an interactive infographic as a resource for designing and manufacturing a hardware product. The infographic visualizes the process from your idea to outsource manufacturing, giving you a step-by-step process for knowing how to design and manufacture a hardware product yourself, with clickable steps and that take you to more in-depth information and advice.

Three key points we like from Learn How to Design Hardware:

- Expect trace routing to take you a few attempts

- Don’t worry if your prototypes come in two shipments, so that bare PCB boards may be inspected before the parts are soldered on to them

- Share the design you have completed within your organization and maybe even as far as the open source hardware movement to get as much feedback as possible and to get improvements from others

Cost: FREE

28. Real World Guide to Hardware Design

@udemy

Udemy is a top provider of online courses. Their Real World Guide to Hardware Design course offers “valuable tips and tricks to save you time, energy and money on your hardware designs.” Instructed by Mike Ingoldby, founder of Trango Engineering, Real World Guide to Hardware Design addresses the basics of developing a hardware product.

Three key ideas we like about Real World Guide to Hardware Design:

- How to set up lab and how to manage your limited budget

- A checklist for avoiding expensive schematic and circuit mistakes

- Select the correct components to make a successful design

Cost: $99

eBooks and White Papers

29. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers

Building Open Source Hardware: DIY Manufacturing for Hackers and Makers is an eBook written by Alicia Gibb and published by Addison-Wesley Professional. The eBook serves as a guide to the hardware product design and manufacturing process. It features the personal experiences of contributors who have worked on DIY, maker, and hardware hacking projects and shares their “proven approaches to design, remixing, fabrication, manufacturing, troubleshooting, licensing, documentation, and running an open source hardware business.”

Three key ideas we like from Building Open Source Hardware: DIY Manufacturing for Hackers and Makers:

- Step-by-step instructions for making derivatives from existing projects

- Avoiding trademark, copyright, patent, and licensing issues

- Developing designs you can prototype and manufacture successfully

Cost: $17.27

30. Advanced Hardware Design for Error Correcting Codes

Edited by Cyrille Chavet and Philippe Coussy, Advanced Hardware Design for Error Correcting Codes is a handy resource for designing and manufacturing a hardware product. The eBook “examines how to optimize the architecture of hardware design for error correcting codes” and delivers a comprehensive discussion of error correcting techniques.

Three key topics we like from Advanced Hardware Design for Error Correcting Codes:

- Optimizing the architecture of hardware design for error correcting codes

- Error correction codes from theory to optimized architecture

- Industrial user needs and advanced error correcting techniques

Cost: $79.99

31. Knowledge Based Engineering (KBE): Key Product Development Technology to Enhance Competitiveness

@Infosys

Infosys, “a global leader in consulting, technology, outsourcing and next-gem services,” offers its own advice on designing and manufacturing a hardware product in this white paper. The hardware product design and manufacturing resource presents knowledge based engineering (KBE) as a crucial component of getting innovative products to market in a faster and more cost-effective manner.

Three key topics we like from Knowledge Based Engineering (KBE): Key Product Development Technology to Enhance Competitiveness:

- How KBE benefits engineering organizations

- Factors influencing an organization’s maturity in its technology use

- Critical KBE success factors

Cost: FREE

32. Methods for Configurable Hardware Design

@Kilopass_

A leading supplier of embedded non-volatile memory cores, Kilopass offers Methods for Configurable Hardware Design, a hardware product design and manufacturing resource. The white paper advocates making devices configurable because of the associated benefits, including more rapid time to market and reduced project schedule risk.

Three key ideas we like from Methods for Configurable Hardware Design:

- There is a growing trend toward enhanced configurability as more platform system on a chip (SoC) architectures become available

- It is possible to add many SoC architectures for a slight incremental cost, or none at all

- To maximize the benefits of establishing a configurable SoC architecture, engineers and designers should have a well-defined common set of hardware components, integrate firmware and system software, and include permanent memory (internal NVM) to store the SoC configuration information securely

Cost: FREE

33. Hardware Software Co-Design

@MistralSoln

A technology design and integration company, Mistral Solutions provides end-to-end services for product development and deployment. Their white paper, Hardware Software Co-Design, compares hardware design and software design and addresses the need for co-design, as well as for “the development flow that enables a designer to take advantage of hardware and software to optimize the solution offering.” Case studies that illustrate hardware and software co-design in a hardware product design are also presented in the paper.

Three key topics we like from Hardware Software Co-Design:

- The advantages and challenges of hardware and software co-design

- Making use of hardware software co-design to optimize design solutions

- Because hardware design brings about real-time performance and software brings about flexibility and configurability, hardware software co-design is the solution to hardware product design

Cost: FREE

Podcasts, Videos, and Webinars

34. Podcast: Peter Merholz Talks Product Design

@intercom

Intercom seeks to make customer communication simple. Their hardware product design and manufacturing resource, a podcast featuring Senior Director of design with Jawbone, Peter Merholz, covers everything from his definition of product management to the “rapidly changing economics of design agencies.”

Three key points we like from Podcast: Peter Merholz Talks Product Design:

- A product manager’s primary function needs to be shipping product

- If you are designing and manufacturing a customer-facing hardware product, the product manager should have a design background

- “There’s more value to be iterating in a prototyping, internal mode when you can iterate more quickly, and you’re still feeling your way forward, than trying to ship something sooner and iterate in public.”

Cost: FREE

35. Lecture 17 – How to Design Hardware Products (Hosain Rahman)

@hosain

Hosain Rahman, founder and CEO of Jawbone, delivers a lecture on how to design hardware products in this video. The central focus of his lecture is the design process for building hardware products that users will love. The transcript of the video is available as well.

Three key ideas we like from Lecture 17 – How to Design Hardware Products (Hosain Rahman):

- Remember that the ultimate goal of designing and manufacturing a hardware product is to improve people’s lives with technology

- The design process needs to shift away from the product and to the individual user of it

- Wearables are going to be at the center of hardware design and manufacturing because of their application to the Internet of Things

Cost: FREE

36. Designing for Future Hardware

A video highlighting Apple developers and their partners, Designing for Future Hardware is all about designing “for tomorrow’s products today.” Hardware designers and manufacturers need to keep in mind that software often is designed before their products are complete or even an idea. This video provides the examples that illustrate that reality.

Three key topics we like from Designing for Future Hardware:

- Design techniques

- Prototyping techniques

- Apps are created for hardware accessories and new products before they are available

Cost: FREE

37. PRG Webinar Agile Hardware Development – Annuvia Case Study (Part II)

@PRG_Mkeer

Product Realization Group (PRG) helps electronic high-tech companies with “rapid new product introduction, compliance, and supply chain” through their product lifecycle services. As part of their Agile Product Development webinar series, PRG founder and CEO Michael Keer presents an Annuvia case study to show the development process involved in prototyping Annuvia’s Beacon.

Three key topics we like from PRG Webinar Agile Hardware Development – Annuvia Case Study (Part II):

- Applying agile software concepts to new hardware products

- Gaining more control by assigning an NPI project manager and following the phase-gate process

- Utilizing agile hardware “sprints” and rapid prototyping to save time and lower costs

Cost: FREE

38. Joe Justice Explains Agile Hardware Design

@SolutionsIQ

Offering comprehensive solutions for companies seeking to adopt agile practices, SolutionsIQ can help from the team level to executive management. In this video for designing and manufacturing a hardware product, we learn about the process involved in designing and building a 100 MPG road car (that just so happened to beat Tesla Motors in the X-Prize) in three months without any capital investment or paid employees. The video features Joe Justice, WIKISPEED founder and Solutions IQ consultant.

Three key ideas we like from Joe Justice Explains Agile Hardware Design:

- Constructing the car entirely with off-the-shelf parts

- Using an entirely modular design

- Using a new process for carbon-fiber body construction that costs a fraction of the traditional process

Cost: FREE

39. Defining Lean Hardware Development

@fictiv

Fictiv delivers a platform for prototyping hardware and serves as the fastest way to order 3D printed parts. Defining Lean Hardware Development is their resource for designing and manufacturing a hardware product that features four hardware startups discussing lean development and the ways in which it influences their product development process.

Three key topics we like from Defining Lean Hardware Development:

- Lean product development

- The hardware revolution

- Developing hardware products in a lean product development environment

Cost: FREE

40. “Manufacturing, Design, Hardware, and the Code That Makes Sense Of It All,” Joi Ito and Jon Bruner

@OReillySolid

O’Reilly Solid sits at the intersection of hardware, software, and the Internet of Things, as “Solid brings together the people building our software-enhanced, networked physical world.” In this nearly half-hour video, Joi Ito and Jon Bruner explain how hardware may be “on the brink of a similar disruption” to that of software development and deployment.

Three key points we like from “Manufacturing, Design, Hardware, and the Code That Makes Sense Of It All,” Joi Ito and Jon Bruner:

- Consumers are beginning to demand that their objects do more than ever before

- Hardware products and devices that were strictly mechanical now are “seamless blends of hardware and software”

- Software and hardware are becoming one

Cost: FREE

41. Manufacturing for Hardware Startup – BERG @ HS LAB

@bergcloud

Hardware Startup Lab delivers insights and resources for and from hardware startups. Their video, Manufacturing for Hardware Startup – BERG @ HS LAB, features Andy Huntington, Hardware Producer and Designer at BERG.

Three key topics we like from Manufacturing for Hardware Startup – BERG @ HS LAB:

- Manufacturing processes behind real-world hardware products

- Building a physical product is not like building software

- It’s never been easier to build a physical product

Cost: FREE

42. The New Way to Build Hardware Products: Tips and Strategies – Dragon Innovation @ HS LAB

@dragoninnovate

Dragon Innovation, in conjunction with entrepreneurs, works to launch hardware products and scale companies. Their hardware product design and manufacturing resource, a YouTube video, features Dragon Innovation CEO and co-founder Scott Miller describing new strategies for successfully manufacturing startup products.

Three key points we like from The New Way to Build Hardware Products: Tips and Strategies – Dragon Innovation @ HS LAB:

- Crowdfunding provides a good gauge for consumer interest in a hardware product

- If you’re building high-volume, China is one of the best places to manufacture

- There is a good chance that entrepreneurs don’t know all that they need to know in terms of hardware, packaging, etc.

Cost: FREE

43. Building an Internet Connected Product: Webinar

@Design_1st

Design 1st is at the forefront of Canadian innovation, “from napkin sketch to design of well engineered products.” Their webinar, Building an Internet Connected Product, is a helpful hardware product design and manufacturing resource, as it covers the opportunities associated with the product development for the IoT.

Three key topics we like from Building an Internet Connected Product: Webinar:

- The Internet of Things is the fastest growing hardware product category

- Nearly endless possibilities and opportunities for developing an IoT product exist today

- Companies developing IoT products must blur the lines between industrial design, mechanical engineering, software programming, electronics, wireless networking and UX design

Cost: FREE

Tips

44. 4 Tips for Manufacturing Your First Hardware Product

@fictiv

This tips article from Fictiv highlights the experiences of Massimo Andreasi Bassi, CTO of Luna, and shares his experience developing his first hardware product. Bassi shares the lessons he learned to help him navigate the manufacturing process.

Three tips we like from 4 Tips for Manufacturing Your First Hardware Product:

- Build a team that will help you in the areas you need help the most

- Seek out help from design for manufacturing experts because they have experience in “the requirements of design manufacturability”

- Design for assembly, not just for manufacturability

Cost: FREE

45. 8 Tips for Jumpstarting a Hardware Startup

@technicalhumans

Jon McKay, co-founder of Technical Machine, started a hardware company with his friends. With crowdfunding, they ventured into designing and manufacturing a hardware product because they couldn’t find any hardware that had “the functionality our software required.” They wanted to move quickly, so they approached their startup with an agile model. In this Tessel Blog post, McKay shares tips from what he learned about building a hardware company quickly, coming from a web background.

Three tips we like from 8 Tips for Jumpstarting a Hardware Startup:

- Make the easiest, quickest prototype possible and get user feedback, because all lean startup rules still apply for hardware companies

- Order evaluation boards for the chips you will use

- Use reference designs so that your technology will work more reliably

Cost: FREE

46. Apple’s Top 10 Tips for Great Product Design

@Computerworld

Computerworld shares some of Apple’s secrets to success in hardware product design in this tips article. With all of Apple’s success, it’s very tempting to try to copy their model. But, Apple can approach hardware product design and manufacturing much differently than startups because of its sheer size. These tips are more practical than simply doing as Apple does.

Three tips we like from Apple’s Top 10 Tips for Great Product Design:

- Maintain a high level of quality in all that you do

- Don’t leave your designs static: embrace change and be willing to ditch successful products to design and manufacture new ones

- Stay ahead of competitors by delivering “new to market technologies with compelling new products people need”

Cost: FREE

47. Tips for Doing Effective Hardware/Firmware Codesign: Part 2

@embedded_com

Embedded.com is an embedded systems resource for designers and developers. This embedded.com blog post, is the second part of a series excerpted from author Gary Stringham’s Hardware/Firmware Interface Design, in which he “provides best practices techniques for performance, power-on interactions, communications and control.”

Three tips we like from Tips for Doing Effective Hardware/Firmware Codesign: Part 2:

- Use proven techniques “to maximize the performance at the hardware/firmware interface without incurring too much cost in the platform”

- Appropriately size receive and transmit buggers to allow for efficient communication between hardware and firmware

- “Make the chip tunable so that firmware can adjust performance characteristics such as bus priorities and clock speeds”

Cost: FREE

48. 10 Software Tips for Hardware Engineers

@EDNcom

It’s important to keep in mind that a thorough understanding of how software affects and interacts with hardware is required for embedded systems designs. This means that hardware engineers need to remember that designing software for their hardware products often requires a completely opposite approach. Jacob Beningo, in this EDN Network blog post, offers 10 tips for hardware engineers who are beginning to develop software for their hardware products.

Three tips we like from 10 Software Tips for Hardware Engineers:

- Develop an architectural diagram of the software using flowcharts before you start writing code, to get an idea of the parts and components that will be required for the application

- Use state machines to easily develop software that “is modular, maintainable, and easy to understand.”

- Use the new object-oriented paradigm and define variables in the smallest possible scope

Cost: FREE

49. No One Ever Told Me: 6 Tips for Hardware Manufacturing from DrinkMate

@SMasavage

@Fulfillrite

@DrinkMateBAC

CEO and founder of Edge Tech Labs, Shaun Masavage shares tips for designing and manufacturing a hardware product that he wishes someone had told him when he set out to develop DrinkMate. He also contends that the challenges faced when developing hardware products are unique to hardware development, which may contribute to the reason for there being so few people creating hardware products.

Three tips we like from No One Ever Told Me: 6 Tips for Hardware Manufacturing from DrinkMate:

- Use a micro controller from a company or manufacturer that has invested in tutorials and sample firmware for its products to save you time on the firmware coding

- Get as many samples of your PCB and enclosure samples and test them to see what makes them fail; if you find a weak design characteristic, discuss it with the manufacturer, who may make the design change or have ideas for how to solve the issue

- Use crowdfunding with a well-planned campaign

Cost: FREE

50. Tips on Product Design and Manufacturing

@dragoninnovate

The Dragon Innovation team offers their tips on product design and manufacturing in this Flexport blog post. Dragon Innovation’s experts understand all of the intricacies of hardware product design and manufacturing, and they offer advice to help any hardware company build worthwhile products of the highest quality. The post acts as a roundup of sorts, with links to articles featuring some of Dragon Innovation’s best tips.

Three tips we like from Tips on Product Design and Manufacturing:

- From beginning to end, your hardware product should “speak visually to consumers and [make] them crave interaction with it”

- When choosing a supplier, compare variables of multiple factories and then decide which one will best work with you to ensure your product success

- To cut costs most effectively, take a step back “to look within the context of the total product development lifecycle” and see where you can save money

Cost: FREE