A Definition of Non-Tactile Copper Flex Membrane Switches

Non-tactile membrane switches do not feature a snap action when a user presses them. Because they do not provide feedback to the user, non-tactile membrane switches often feature embedded light emitting diodes

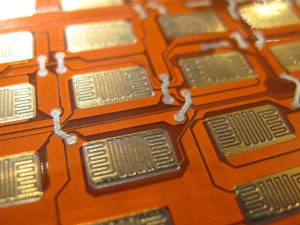

Non-tactile membrane switches constructed of copper flex are typically produced using polyimide (Kapton) as the base material. Very thin sheets of copper are laminated to the flexible film substrate and then etched away chemically, leaving copper traces behind. Copper flex membrane switches may be constructed as single-sided, with conductive traces on one side of the film substrate, as double-sided, with conductive traces on both sides of the film substrate, or as multi-layer flex, to create a laminated sandwich of numerous layers with conductive traces. Typically, copper flex membrane switches have the ability to provide higher density traces and feature SMT low profile components.

Benefits of Non-Tactile Copper Membrane Switches

Non-tactile copper flex membrane switches are known for their high reliability, as they have been known to respond to more than 5 million actuations. That’s just one of the reasons that non-tactile membrane switches are cost effective and meet the demands of a wide range of applications. Non-tactile copper flex membrane switches also are well suited to smaller designs that have dense circuit patterns or trace routing limitations.

Other benefits of non-tactile copper flex membrane switches include:

- Lower electrical resistance than silver flex membrane switches

- Higher conductivity than traditional silver flex membrane switches

- Tight trace routing capabilities

- Thin profiles and flexibility

- Tin-lead, nickel, or gold plating options

- LEDs and other components may be soldered

- Graphic overlays may be digitally printed, screen printed, or include a combination of both

- Graphic overlays may incorporate transparent or tinted window displays

- May feature selective textures and UV hardcoat surface finishes

Disadvantages of Non-Tactile Copper Flex Membrane Switches

Some users prefer tactile copper flex membrane switches to non-tactile copper flex membrane switches because they prefer to feel the snap action when they press the switch. With appropriate backlighting and indicator lights, this issue typically is solved quite easily. Another disadvantage of non-tactile copper membrane switches is their cost: copper flex membrane switches tend to be much more expensive then silver flex switches, because of the cost of the polyimide material and the chemical etching process. That process also is not an environmentally-friendly process.

Backlighting Options for Non-Tactile Copper Membrane Flex Switches

- Light Emitting Diodes (LEDs) – LEDS are a popular, low-cost, point-source lighting method for non-tactile copper flex membrane switches. Primary used as indicator lights for this type of membrane switch, LEDs emit little heat and are available in red, yellow, green, blue, white, and bi-color packages. LEDs also are available in a range of intensities, and some are specifically designed for outdoor applications. LEDs may be through-hole soldered in non-tactile copper membrane switches, which enhances their durability.

- Electroluminescent (EL) Lighting – EL lamps feature a high efficiency conversion process that minimizes power consumption and losses due to heat or IR emissions. Non-tactile copper flex membrane switches that feature EL lighting are better suited to low and no-light applications where the backlight is not constantly

on, because the phosphors have a tendency to decay with extended use at high voltages and frequencies. - Fiber Optic Lighting – Fiber optics are cost-effective and allow for more uniform backlighting across a broader area of the non-tactile copper flex membrane switch keypad. Fiber optic lighting often uses light from LEDs and is known for a more even distribution of light under the graphics through the use of very thin plastic fibers.