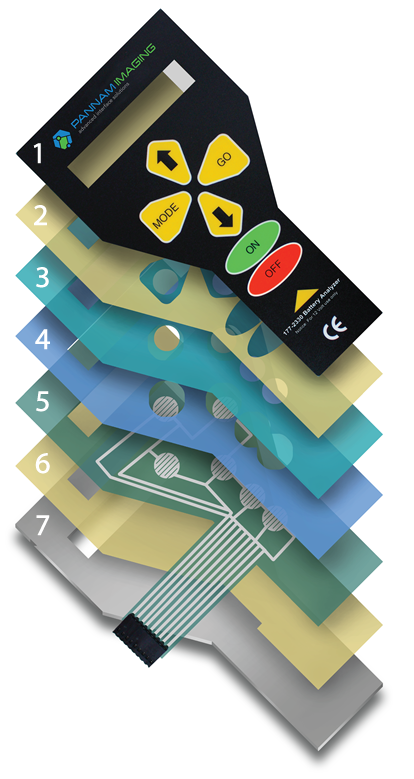

A membrane switch is a critical component of product design, but the membrane switch assembly itself is actually a series of individual layers and components, each serving a specific function. It’s the right combination of the various possible layers that determine the functionality of the final membrane switch assembly, and ultimately, the success of the final product.

For this reason, it’s helpful for product designers and manufacturers to have an understanding of the various components that make up a membrane switch assembly, so that they can make informed decisions in conjunction with engineers to determine the best combination of components for the desired result. Here’s a look at the different components of a membrane switch assembly.

1. Graphic Overlay – This is the top layer of a membrane switch assembly, and it’s a key component of the final product as it serves as the visual representation of the product’s control panel. The graphic overlay is the part of the membrane switch assembly that the user sees, so the look and feel of this component can have a major impact on the visual appeal of a product.

Polyester is often selected as the preferred material for the graphic overlay, as it offers superior chemical resistance and generally has a longer flex life than materials such as polycarbonate. The graphic overlay can be printed with any color, color combination, or graphics.

Durability is also a consideration in choosing the right graphic overlay, as well as performance. For instance, the right thickness is necessary to achieve a desired level of tactile feedback when combined with other layers, such as stainless steel domes. You’ll also want to select materials and thickness durable enough to continue providing a consistent level of tactile feedback through repeated switch cycles.

In general, thicker graphic overlays provide a heavier feel for increased tactile feedback. A membrane switch design and engineering team should carefully weigh the many considerations for every application to recommend the best possible combination of materials and components for the best results.

2. Overlay Adhesive – Usually an acrylic adhesive, this layer secures the graphic overlay to the top circuit layer of a membrane switch assembly. Durability is a key consideration for an overlay adhesive, as the graphic overlay separating from the circuit layer below over time diminishes the quality of the product.

Optional EL Layer or Other Backlighting Options – EL backlighting is one of several backlighting options that can be used in membrane switch assembly design. Embedded LEDs or fiber optic backlighting may be used as alternatives.

EL is a very thin layer that emits little heat, and it can be cut into any shape and layered within the membrane switch assembly, offering great flexibility in design. This is a commonly used backlighting option found in products such as mobile phones, pages, and automotive dashboards, as well as the Timex Indigo Watch.

For fiber optic backlighting, sheets of fiber optic cloth are cut into specific shapes and sizes, resulting in a thin, flexible lighting layer positioned between the overlay and the dome switches. Fiber optics offers a number of benefits for membrane switch assembly backlighting, including low power consumption, compact size, low heat, long life span, and flexibility in design options.

LED backlighting is a lower-cost alternative to EL and fiber optic backlighting. It’s used selectively to create backlighting in select areas of a membrane switch, such as behind certain text or graphics.

3. & 5. Circuit Layers – The circuit layer is actually the combination of several other components. As there are different types of membrane switch assemblies, the specific construction of this layer differs accordingly. Additionally, there are several design considerations and customizations that occur in this layer to produce the desired result. The circuit layer may include:

- Dome retainer (for tactile feedback)

- Conductive inks

- Circuit

- Circuit spacer (separating the top and bottom circuit layers)

Domes are essential for creating tactile feedback. These are typically constructed of polyester or stainless steel. Stainless steel is often selected as the material of choice, due to its lower cost and the tactile experience stainless steel domes offer.

6. Rear Adhesive Layer – This layer is sometimes considered a part of the circuit layer, although it’s worth discussing as a separate component due to the critical purpose it serves and the important considerations in selecting the right adhesive for your product’s requirements. The rear adhesive layer bonds the membrane switch assembly to the product or the rigid backing, so it must be durable enough to withstand the test of time.

A 3M 467MP pressure-sensitive adhesive is commonly used for the rear adhesive layer. But in some cases, the membrane switch assembly must adhere to a rough surface, in which case a 3M 468MP pressure-sensitive adhesive may be used for better adherence and durability. When the membrane switch must adhere to a low surface energy material such as powder coated paint or polyproplylene, a modified acrylic adhesive such as 3M9471LE or 3M9472LE is recommended. Bond strength is also dependent on the way it’s applied, so it’s important to follow best practices for the best results.

7. Back Panel – This rigid support layer is an optional component, but is often used to provide additional structural support to a membrane switch assembly. The back panel is often constructed of aluminum, which can be bare, alodined, painted, or anodized, depending on the product requirements.

The back panel can also be manufactured with studs, holes, or stand-offs to suit the application. When a membrane switch assembly is combined with a back panel, the resulting combination is called a membrane switch panel. While there are many companies manufacturing membrane switches and individual components, few companies offer the design and manufacture of full membrane switch panels.

While it’s helpful to have an understanding of the many components that, together, create a membrane switch assembly, working with an expert design and engineering team with experience creating ideal membrane switch assembly solutions for a variety of applications ensures that the final product is well-suited for your product’s functionality and requirements. Experienced membrane switch design engineers are able to recommend the best components and combinations to produce the precise look, feel, and experience you’re seeking for your final product. Knowing the various components and materials, as well as the function of each, will help you interface readily with the design team to communicate product specifications.

Looking for membrane switch product samples or would you like to set up a free design consultation? You can call us directly by phone (216) 475-6704 or email Customer_Service@Pannam.com